Summary

Key questions

- To what extent is the decrease in the EU’s industrial energy consumption after the economic crisis due to energy efficiency improvements (as measured through the ‘unit consumption’ of industrial branches)?

- What has been the impact of changes in production level of industrial branches?

This policy brief analyses the relative importance of ‘activity’, ‘structural’ and ‘unit consumption’ effects on the variation of the industrial energy consumption in the EU since 2007, based on ODYSSEE data.

Lead authors: Francis Altdorfer (ECONOTEC, Belgium)

Reviewers: Joost Gerdes (ECN, Netherlands), Theodoros Zachariadis (Cyprus University of Technology)

Introduction

The economic crisis sparked by the global financial crisis of 2007-2008 has had an impact on gross domestic product (GDP), energy consumption and carbon dioxide (CO2) emissions.

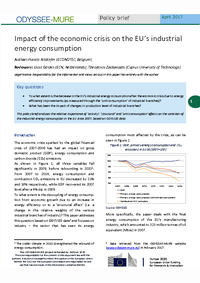

As shown in Figure 1, all three variables fell significantly in 2009, before rebounding in 20101. From 2007 to 2014, energy consumption and combustion CO2 emissions in EU decreased by 11% and 18% respectively, while GDP recovered its 2007 level after a 4% dip in 2009.

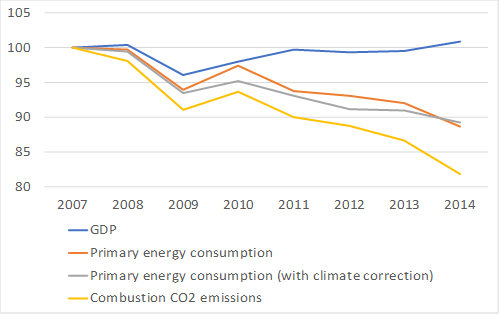

To what extent is the decoupling of energy consump¬tion from economic growth due to an increase in energy efficiency or to a ‘structural effect’ (i.e. a change in the relative weights of the various industrial branches of industry)? This paper addresses this question based on ODYSSEE data2 and focuses on industry – the sector that has seen its energy consumption most affected by the crisis, as can be seen in Figure 2.

Figure 1: GDP, primary energy consumption and CO2 emissions in EU28 (2007=100)

Source: Odyssee

More specifically, the paper deals with the final energy consumption of the EU’s manufacturing industry, which amounted to 323 million tonnes of oil equivalent (Mtoe) in 2007.

Figure 2: Final energy consumption in EU28 (2007=100)

Source: Odyssee

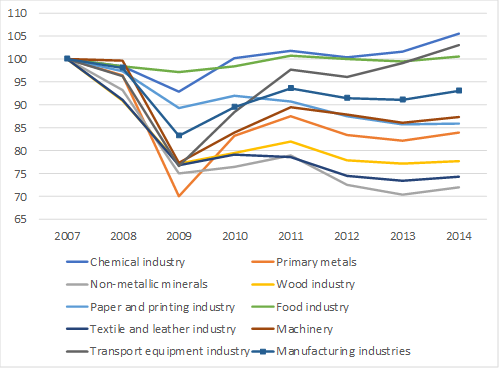

Structural effect

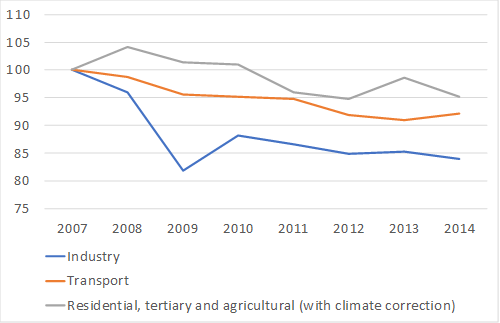

Figure 3 shows that the impact of the crisis varied across the different branches of industry. Some lost ground over the period 2007-2014 (non-metallic minerals, textiles and leather, primary metals, wood, ‘paper and printing’ and machinery). Others (chemicals, food and transport equipment industries) grew faster than the production index of manufacturing industries3, which denotes an evolution in the structure of industry.

Figure 3: Production index by industrial branch in EU28 (2007=100)

Source: Odyssee

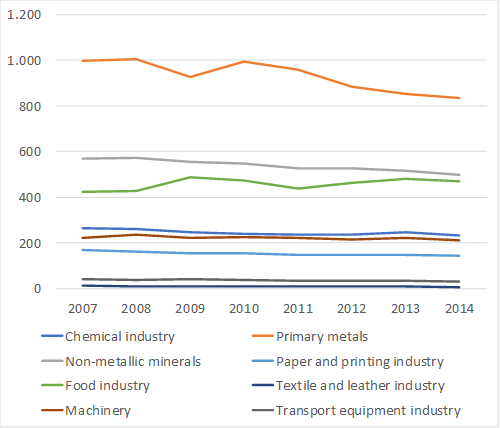

In the meantime, there is a large dispersion in the energy intensity4 levels across branches (Figure 4). Together with the difference in the evolution of the production by branch, this creates a structural effect in the evolution of the energy consumption, which may be either positive (increased consumption because of a shift towards more energy intensive branches) or negative (reduced consumption).

Figure 4: Final energy intensity in EU28 (toe/M€2005)

Source: Odyssee

Change in unit consumptions

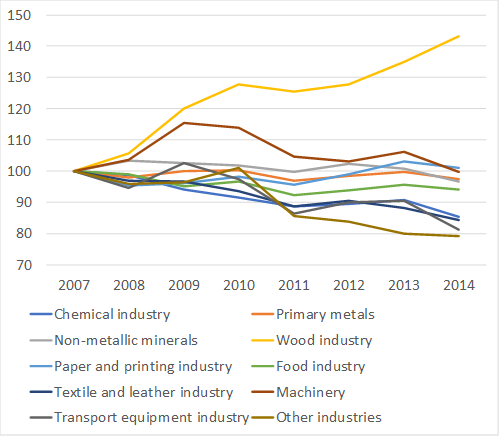

Unit consumptions (measured as a ratio of energy consumption to industrial production index) have generally decreased since 2007, with the notable exceptions of the wood industry, machinery, non-metallic minerals, and ‘paper and printing’ (Figure 5). It should be noted that the unit consumptions may be influenced by intra-branch structural effects (see later) and by increasing or decreasing shares of electricity (as electricity is considered as final energy and is generally more efficient than fuels).

Figure 5: Unit consumption index by branch for EU28 (2007=100)

Source: Odyssee

There is a negative correlation between the variations of unit consumptions and those of production levels (Figure 3) – unit consumptions tend to improve when output levels rise (which is often related to a better use of production capacities) and vice-versa.

Breakdown of the variation in energy consumption since 2007

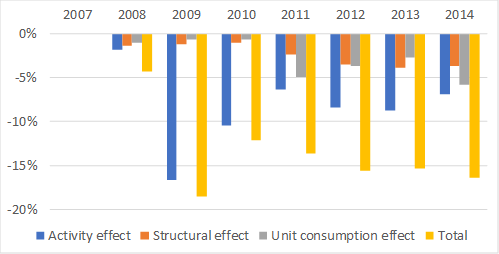

Figure 6 gives a breakdown in the variation in energy consumption of EU28 since 2007 into three components – (a) an activity effect (the same percentage variation as that of the production index of manufacturing industry as a whole); (b) a unit consumption effect (the difference between the observed energy consumption and the one that would have taken place had the unit consumption of each branch5 stayed at its level of 2007); and (c) a structural effect (calculated by difference6).

It shows that, in comparison with 2007, the significant reduction in energy consumption that happened in 2009 is essentially an activity effect (i.e. a percentage reduction almost equal to that of the output of manufacturing industry). In 2010, the reduction (yellow bar) is more modest, but remains essentially an activity effect. In the subsequent years, the structural and unit effects also have a significant contribution to the reduction in energy consumption.

Figure 6: Breakdown of the energy consumption variation 2007-2014 in EU28 manufacturing industry (% of energy consumption in 2007)

Source: Odyssee, own calculations

In 2014, the activity, structural and unit consumption effects represent a reduction of respectively 7%, 4% and 6% of the consumption in 2007. In absolute terms, this is respectively 22 Mtoe, 12 Mtoe and 18 Mtoe.

The unit consumption effect gives an indication of the level of energy savings (energy efficiency improve¬ment). It comprises not only the impact of energy efficiency policies but also that of ‘natural’ energy efficiency improvements (i.e. those due to technical progress and investments in new equipment).

However, this indicator remains imperfect, mainly because of the structural effects taking place inside each of the branches. Examples of such intra-branch structural effects are: (a) product shifts from energy-intensive products towards less energy-intensive products or vice-versa (such shifts may have a significant impact in the chemical industry, which comprises pharmaceuticals and energy intensive petrochemicals or other base chemicals); (b) shifts in types of raw material, like the replacement of clinker by blast furnace slag in the cement industry; (c) process shifts, like the replacement of oxygen steel with electric steel. Some of these intra-branch structural effects may or may not be considered as energy savings, depending on the definition of energy savings that is used.

These intra-branch structural effects may be either positive or negative. Hence, energy savings may be underestimated or overestimated.

Breakdown for selected countries

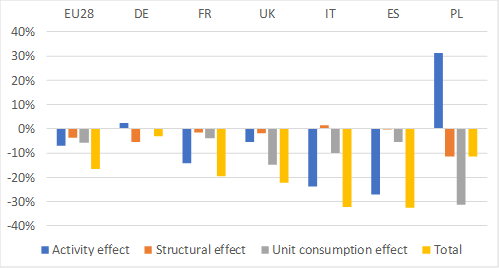

There is a large disparity in the breakdown of the energy consumption variation across individual countries (see Figure 7, providing results for the six largest energy consuming countries – representing 69% of the total EU28 primary energy consumption – obtained using the same data source and calcula-tions).

Figure 7: Breakdown of energy consumption variation 2007-2014 for six countries (% of energy consumption of manufacturing industry in 2007)

Source: Odyssee, own calculations

Among these countries, the unit consumption effect over the 2007-2014 period extends from 0% in Germany (where there is actually an increase for ‘chemical industry’ and ‘wood industry’) up to -31% in Poland. The structural effect ranges from +2 % in Italy to -11 % in Poland for the same period. Of particular note is the 31 % increase in activity effect in Poland.

Breakdown by branch

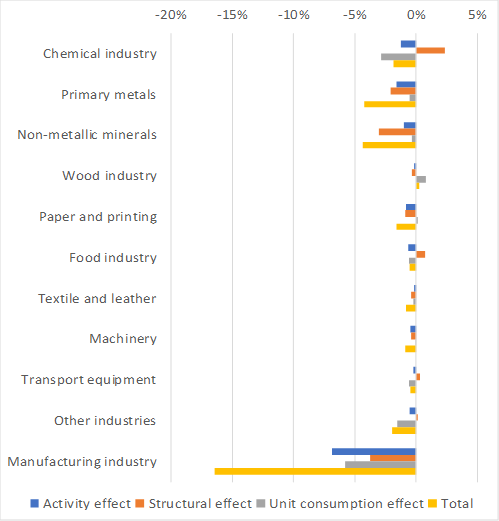

Figure 8 gives a breakdown by branch of the variation in EU28 energy consumption for the period 2007-2014. The structural effect is mainly due to ‘non-metallic minerals’ (-3.0%) and ‘primary metals’ (-2.1%), and is partly compensated by ‘chemical industry’ (+2.3%).

Figure 8: Breakdown of the EU28 energy consumption variation 2007-2014 by branch (% of energy consumption of manufacturing industry in 2007)

Source: Odyssee, own calculations

The unit consumption effect is mainly due to the chemical industry.

It should be noted that, within the same branch, energy savings in countries with a negative unit consumption effect may be hidden by increases in unit consumption (due to a shift in products for example) in other countries.

Conclusions

The analysis carried out for the European manufac-turing industry shows that, compared with 2007, the significant reduction in energy consumption in 2009-2010 can almost entirely be attributed to the decline in industrial production. The later evolution of energy consumption is due not only to industrial activity, but also to a reduction in branch unit consumptions (a proxy for energy efficiency improvement) and to a significant structural effect (a smaller weight of energy intensive branches), which allows a decou¬pling of energy consumption from production. It should be noted that significant disparities do exist across branches and countries.

Notes

- 1: The colder climate in 2010 strengthened the rebound of energy consumption.

- 2: Data retrieved from the ODYSSEE-MURE website in February 2017.

- 3: This production index is an average of the production indexes of the various branches, weighted by the share of each branch in the value added of manufacturing industry.

- 4: The energy intensity is defined as the energy consumption (here expressed in tonnes of oil equivalent (toe)) divided by the value added of the branch (here expressed in million euros of base year 2005).

- 5: For this analysis, a disaggregation of manufacturing industry into 10 branches was used.

- 6: The structural effect is equal to the variation in energy consumption that would have taken place if the unit consumption of each branch had stayed at its level of 2007, minus the activity effect.